Product

Contact us

Factory Address: Building 1, No.5, Chuangye Road, Zhuze Town, Liyang City

Email: williams@kzrind.com

Website: www.kzrind.com

EP conveyor belts (Polyester conveyor belts)

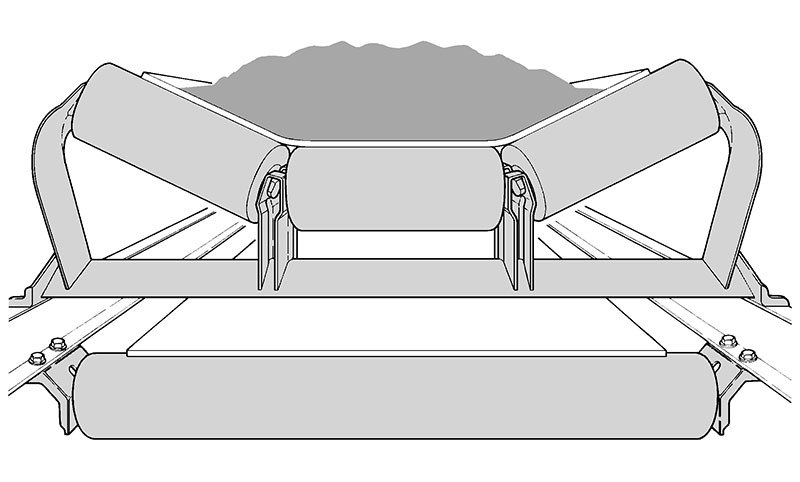

EP conveyor belt,also called polyester conveyor belt.Force body skeleton for EPcanvas(with polyester,longitudinal transverse for nylon).have light weight, high modulus, highimpact,use small elongation,eiastic and into a good groove, resistant to moisture andinsect-resistant eat by moth,etc.suitabie for long-distance conveying material under thecondition of high load high speed.

Key words:

category:

Detailed introduction

Application

It is suitable for conveying materials under medium and long distance, high load and high speed condition.

Features

High initial modulus,low elongation, excellent grooving, good water resistance.

Specification and technical data of multi-ply polyester conveyor belt

| Fabric type | Fabric structure | Fabric specs | Ply thickness (mm/p) | Strength series (N/mm) | Cover thickness (mm) | Width(mm) | Length(m) | ||||||

| Warp | Weft | 2-ply | 3-ply | 4-ply | 5-ply | 6-ply | Top cover | Bottom cover | |||||

| Polyester(EP) | Polyester | Polyamine | EP-100 | 0.85 | 200 | 300 | 400 | 500 | 600 | 0~ 20 | 0~ 10 | 400~3000 | ≤500 |

| EP-125 | 0.90 | 250 | 375 | 500 | 625 | 750 | |||||||

| EP-150 | 0.95 | 300 | 450 | 600 | 750 | 900 | |||||||

| EP-160 | 0.95 | 320 | 480 | 640 | 800 | 960 | |||||||

| EP-200 | 1.10 | 400 | 600 | 800 | 1000 | 1200 | |||||||

| EP-250 | 1.25 | 500 | 750 | 1000 | 1250 | 1500 | 0~ 30 | 0 ~ 15 | 500~3000 | ||||

| EP-300 | 1.45 | 600 | 900 | 1200 | 1508 | 1800 | |||||||

| EP-350 | 1.65 | 1050 | 1400 | 1750 | 2100 | ||||||||

| EP-400 | 1.75 | 1600 | 2000 | 2400 | 600~3000 | ||||||||

| EP-450 | 2.30 | 1800 | 2250 | 2700 | |||||||||

| EP-500 | 2.55 | 2000 | 2500 | 3000 | 800~3000 | ||||||||

| EP-550 | 2.65 | 2200 | 2750 | 3300 | |||||||||

| EP-630 | 3.80 | 2520 | 3150 | 3780 | |||||||||

Adhesion and elongation of the belt

| Belt carcass | Adhesive strength | Elongation | |||

| Items | Between plies (N/mm) | Between cover rubber and carcass(N/mm) | Full thickness elongation at reference load in the longitudinal direction (%≤) | ||

| Rubber thickness 0.8~1.5mm | Rubber thickness >1.5mm | ||||

| EP canvas | Average value of all samples (N/mm) | ≥4.5 | ≥3.2 | ≥3.5 | 4 |

| Minimum peak value of all specimens(N/mm) | ≥3.9 | ≥2.4 | ≥2.9 | ||

Cover properties of the belts

| Cover grade | Tensile strength ≥ (Mpa) | Elongation ≥ (%) | Abrasion ≥ (mm3) | The middle value of tensile strength and elongation rate at break shall be equal or greater than corresponding values before aging (%) |

| H | 24 | 450 | 120 | 75 |

| D | 18 | 400 | 100 | 75 |

| L | 15 | 350 | 200 | 75 |

Recommended minimum roller diameter (for reference only)

| Item | recommended to use minimal conveyor belt roller diameter(mm) | ||||||

| 2-PLY | 3-PLY | 4-PLY | 5-PLY | 6-PLY | 7-PLY | 8-PLY | |

| EP100 | 200 | 250 | 315 | 400 | 500 | 630 | 800 |

| EP125 | 200 | 250 | 315 | 400 | 500 | 630 | 800 |

| EP150 | 250 | 400 | 500 | 630 | 800 | 1000 | 1250 |

| EP200 | 315 | 500 | 630 | 800 | 1000 | 1000 | 1250 |

| EP250 | 400 | 630 | 800 | 1000 | 1250 | 1400 | 1600 |

| EP300 | 500 | 630 | 800 | 1000 | 1250 | 1400 | 1600 |

| EP400 | 630 | 800 | 1000 | 1250 | 1400 | 1600 | 1800 |

| EP450 | 630 | 800 | 1000 | 1250 | 1400 | 1600 | 1800 |

| EP500 | 800 | 1000 | 1250 | 1400 | 1800 | ||

| EP630 | 1000 | 1250 | 1400 | 1600 | 1800 | ||

- Why choose us? -

The core business of Kezhirun is the manufacture of conveyor series products (belt conveyors, pipe conveyors, screw conveyors, chain conveyors, non-standard customized equipment), supporting various specifications of rubber conveyor belts (Pipe conveyor belts ,Profiled conveyor belts,high Abrasion resistant conveyor belt,Impact Resistant conveyor belt, Endless conveyor belts,Steel conveyor belts,Nylon conveyor belts,Polyester conveyor belts,High heat resistant conveyor belt, oil resistant conveyor belts, Acid and alkali resistant conveyor belts, Cold resistant conveyor belts and flame retardant conveyor belts of textile construction for general use,Sidewall conveyor belts, special-shaped conveyor belt).

Professional after-sales personnel provide technical support

Technical exchange, skills training, joint education and maintenance team

Quick response from multiple service points

Emergency rescue service

Tailor-made on-site selection and modification to reduce customer costs

Key customers, key products, build files

A number of product technology patents High-quality product installation operation and maintenance team

Design, install and use the whole process solution

get a quote

Enter product details or other specific requirements to receive an accurate quote. We will reply within 24 hours.