Product

Contact us

Factory Address: Building 1, No.5, Chuangye Road, Zhuze Town, Liyang City

Email: williams@kzrind.com

Website: www.kzrind.com

Steel cord conveyor belts

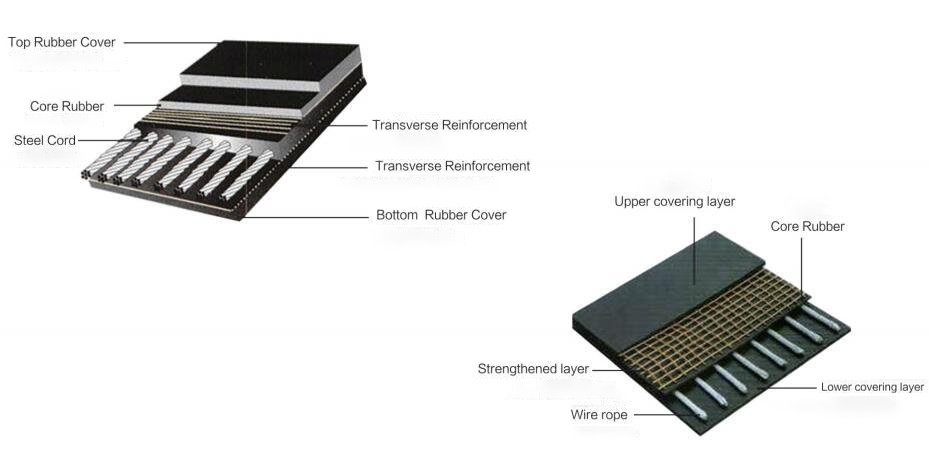

Ordinary steel cord conveyor belt skeleton material adopt high strength steel wire rope, after cold pressing molding and core rubber and rubber after vulcanization process.

Key words:

category:

Detailed introduction

The product description

Ordinary steel cord conveyor belt skeleton material adopt high strength steel wire rope, after cold pressing molding and core rubber and rubber after vulcanization process.

Application area

Steel cord conveyor belt is widely used in distributed occasion, cement,port,coal,mining, power plants, metallurgy,quarries and chemical industry,etc.

Applicable to the main conveyor line long-distance conveying,roadway conveying,loading machine,inclined conveyor,other required delivery.

Product features

Tensile strength,use small elongation,impact,resistant,good into a groove,suitable for long distance,large capacity and high speed conveying.

1.use galvanized open wire rope.

2.than the same strength of fabric core conveyor belt good flexible,the requirements of the small roller diameter.

3.using galvanized open wire rope and steel wire rope has excelient bonding properties of the adhesive material,make the steel wire rope and core glue together,impact resistance long service life.

4.the use of advanced production technology,uniform arrangement,wire rope tension, balanced running, not easy running deviation.

5.according to the customer special request to join a layer or two laceration resistant network, in order toreduce on the conveyor belt longitudinal tear.

6.excellent troughabity:core without transverse frame,easy to form deep groove shape, more material,and prevent the scattered.

Product categories

Ordinary wire conveyor belt,with strengthening layer laceration resistant wire conveyor belt.

ST series of main technical parameters of steel cord conveyor belt

| Specfications and technical parameters | ST 630 | ST 800 | ST 1000 | ST 1250 | ST 1600 | ST 2000 | ST 2500 | ST 3150 | ST 3500 | ST 4000 | ST 4500 | ST 5000 | ST 5400 | ST 6300 | ST 7000 | ST 7500 |

| The longitudinal tensile strength(mm) | 630 | 800 | 1000 | 1250 | 1600 | 2000 | 2500 | 3100 | 3500 | 4000 | 4500 | 5000 | 5400 | 6300 | 7000 | 7500 |

| Wire rope maximum nominal diameter(mm) | 3 | 3.5 | 4 | 4.5 | 5 | 6 | 7.5 | 8.1 | 8.6 | 8.9 | 9.7 | 10.9 | 11.3 | 12.3 | 13.5 | 15 |

| Wire rope spacing(mm) | 10 | 10 | 12 | 12 | 12 | 12 | 15 | 15 | 15 | 15 | 16 | 17 | 17 | 18 | 19 | 21 |

| Covered in gue thickness(mm) | 5 | 5 | 6 | 6 | 6 | 8 | 8 | 8 | 8 | 8 | 8 | 8.5 | 9 | 10 | 10 | 10 |

| Under the cover rubber thickness(mm) | 5 | 5 | 6 | 6 | 6 | 8 | 8 | 8 | 8 | 8 | 8 | 8.5 | 9 | 10 | 10 | 10 |

| Tape reforence woight(kg/㎡) | 18 | 19.5 | 22.5 | 24 | 25.9 | 31.8 | 36.1 | 40.4 | 43.8 | 45 | 45 | 50.7 | 53.4 | 59.6 | 63.7 | 68.7 |

| The width(mm) | The number of wire rope | |||||||||||||||

| 800 | 75 | 75 | 63 | 63 | 63 | 63 | 50 | 50 | 50 | |||||||

| 1000 | 95 | 95 | 79 | 79 | 79 | 79 | 64 | 64 | 64 | 64 | 59 | 55 | 55 | 54 | 49 | 45 |

| 1200 | 113 | 113 | 94 | 94 | 94 | 94 | 76 | 77 | 77 | 77 | 71 | 66 | 66 | 63 | 59 | 54 |

| 1400 | 133 | 133 | 111 | 111 | 111 | 111 | 89 | 90 | 90 | 90 | 84 | 78 | 78 | 74 | 69 | 63 |

| 1600 | 151 | 151 | 126 | 126 | 126 | 126 | 101 | 104 | 104 | 104 | 96 | 90 | 90 | 85 | 80 | 72 |

| 1800 | 171 | 143 | 143 | 143 | 143 | 114 | 117 | 117 | 117 | 109 | 102 | 102 | 96 | 90 | 82 | |

| 2000 | 159 | 159 | 159 | 159 | 128 | 130 | 130 | 130 | 121 | 113 | 113 | 107 | 101 | 91 | ||

| 2200 | 176 | 141 | 144 | 144 | 144 | 134 | 125 | 125 | 118 | 111 | 100 | |||||

| 2400 | 193 | 155 | 157 | 157 | 157 | 146 | 137 | 137 | 129 | 121 | 109 | |||||

| 2600 | 209 | 168 | 170 | 170 | 170 | 159 | 149 | 149 | 140 | 131 | 119 | |||||

| 2800 | 230 | 184 | 184 | 184 | 184 | 171 | 161 | 161 | 151 | 142 | 129 | |||||

| 3000 | 247 | 198 | 198 | 198 | 198 | 185 | 174 | 174 | 148 | 152 | 138 | |||||

| 3200 | 246 | 211 | 211 | 211 | 211 | 198 | 186 | 186 | 158 | 162 | 147 | |||||

The main technical parameter table DIN22131 steel cord conveyor belt

| Specfications and technical parameters | ST 630 | ST 800 | ST 1000 | ST 1250 | ST 1600 | ST 2000 | ST 2500 | ST 3150 | ST 3500 | ST 4000 | ST 4500 | ST 5000 | ST 5400 | ST 6300 | ST 7000 | ST 7500 |

| The longitudinal tensile strength(mm) | 630 | 800 | 1000 | 1250 | 1600 | 2000 | 2500 | 3100 | 3500 | 4000 | 4500 | 5000 | 5400 | 6300 | 7000 | 7500 |

| Wire rope maximum nominal diameter(mm) | 3 | 3.5 | 4 | 4.5 | 5 | 6 | 7.5 | 8.1 | 8.6 | 8.9 | 9.7 | 10.9 | 11.3 | 12.3 | 13.5 | 15 |

| Wire rope spacing(mm) | 10 | 10 | 12 | 12 | 12 | 12 | 15 | 15 | 15 | 15 | 16 | 17 | 17 | 18 | 19 | 21 |

| Covered in gue thickness(mm) | 5 | 5 | 6 | 6 | 6 | 8 | 8 | 8 | 8 | 8 | 8 | 8.5 | 9 | 10 | 10 | 10 |

| Under the cover rubber thickness(mm) | 5 | 5 | 6 | 6 | 6 | 8 | 8 | 8 | 8 | 8 | 8 | 8.5 | 9 | 10 | 10 | 10 |

| Tape reforence woight(kg/㎡) | 18 | 19.5 | 22.5 | 24 | 25.9 | 31.8 | 36.1 | 40.4 | 43.8 | 45 | 45 | 50.7 | 53.4 | 59.6 | 63.7 | 68.7 |

| The width(mm) | The number of wire rope | |||||||||||||||

| 800 | 75 | 75 | 63 | 63 | 63 | 63 | 50 | 50 | 50 | |||||||

| 1000 | 95 | 95 | 79 | 79 | 79 | 79 | 64 | 64 | 64 | 64 | 59 | 55 | 55 | 54 | 49 | 45 |

| 1200 | 113 | 113 | 94 | 94 | 94 | 94 | 76 | 77 | 77 | 77 | 71 | 66 | 66 | 63 | 59 | 54 |

| 1400 | 133 | 133 | 111 | 111 | 111 | 111 | 89 | 90 | 90 | 90 | 84 | 78 | 78 | 74 | 69 | 63 |

| 1600 | 151 | 151 | 126 | 126 | 126 | 126 | 101 | 104 | 104 | 104 | 96 | 90 | 90 | 85 | 80 | 72 |

| 1800 | 171 | 143 | 143 | 143 | 143 | 114 | 117 | 117 | 117 | 109 | 102 | 102 | 96 | 90 | 82 | |

| 2000 | 159 | 159 | 159 | 159 | 128 | 130 | 130 | 130 | 121 | 113 | 113 | 107 | 101 | 91 | ||

| 2200 | 176 | 141 | 144 | 144 | 144 | 134 | 125 | 125 | 118 | 111 | 100 | |||||

| 2400 | 193 | 155 | 157 | 157 | 157 | 146 | 137 | 137 | 129 | 121 | 109 | |||||

| 2600 | 209 | 168 | 170 | 170 | 170 | 159 | 149 | 149 | 140 | 131 | 119 | |||||

| 2800 | 230 | 184 | 184 | 184 | 184 | 171 | 161 | 161 | 151 | 142 | 129 | |||||

| 3000 | 247 | 198 | 198 | 198 | 198 | 185 | 174 | 174 | 148 | 152 | 138 | |||||

| 3200 | 246 | 211 | 211 | 211 | 211 | 198 | 186 | 186 | 158 | 162 | 147 | |||||

Cover adhesive performance and level

| Test items | Performance indicators | |||||||

| GB9770-2001 | DIN22131 | |||||||

| D grade | H grade | L grade | P grade | W grade | X grade | Y grade | ||

| The tensile strength | mpa≥ | 18 | 25 | 20 | 14 | 18 | 25 | 20 |

| Tensile elongation | %≥ | 400 | 450 | 400 | 350 | 400 | 450 | 400 |

| Taging test(70℃,7days), the change rate tensile strength Tensile elongation change | % | -25~+25 | -25~+25 | -25~+25 | -25~+25 | -25~+25 | -25~+25 | -25~+25 |

| Abrason quantity | ≤ | 90mm3 | 120mm3 | 150mm3 | 200mm3 | 90mm3 | 120mm3 | 150mm3 |

Standards and main indicator of steel cord conveyor belt

| Type | Standards and main indicators |

| Ordinary | GB/T9770,DIN22131,JIS6369,AS133 |

| Flame retardant | MT668,HG2539,DIN22131 |

| General type flame retardant | HG253911,DIN22103,DIN22131 |

| Heat resistance | HG/T2297,ISO4195 |

| Wear resistant | Shao Boer abrasion quantity≤90mm3(W),Shao Boer abrasion quantity≤70m3 AS 1333(A) |

| Heat resistant type grinding | Heat under 125C ,Shao Boer abrasion loss≤150m |

| Acid,alkali,oil type | HG4-846,HG/T3714,RMA(MOP,OR) |

| Hardy type | -50℃-20℃,HG/T3647 Brittleness temperature-50℃-20℃,HG/T3647 |

| Ozone resistance type | 50PPHM 40℃/72H Ozone concentration 50PPHM 40℃/72H not cracked |

Suggested that the steal cord conveyor belt use minimum of conveyor roller diameter

| Specifications | ST 630 | ST 800 | ST 1000 | ST 1250 | ST 1600 | ST 2000 | ST 2500 | ST 3150 | ST 3500 | ST 4000 | ST 4500 | ST 5000 | ST 5400 | ST 6300 | ST 7000 | ST 7500 |

| minimum cylinder diameter | 800 | 1000 | 1250 | 1400 | 1600 | 1800 | 2000 | |||||||||

- Why choose us? -

The core business of Kezhirun is the manufacture of conveyor series products (belt conveyors, pipe conveyors, screw conveyors, chain conveyors, non-standard customized equipment), supporting various specifications of rubber conveyor belts (Pipe conveyor belts ,Profiled conveyor belts,high Abrasion resistant conveyor belt,Impact Resistant conveyor belt, Endless conveyor belts,Steel conveyor belts,Nylon conveyor belts,Polyester conveyor belts,High heat resistant conveyor belt, oil resistant conveyor belts, Acid and alkali resistant conveyor belts, Cold resistant conveyor belts and flame retardant conveyor belts of textile construction for general use,Sidewall conveyor belts, special-shaped conveyor belt).

Professional after-sales personnel provide technical support

Technical exchange, skills training, joint education and maintenance team

Quick response from multiple service points

Emergency rescue service

Tailor-made on-site selection and modification to reduce customer costs

Key customers, key products, build files

A number of product technology patents High-quality product installation operation and maintenance team

Design, install and use the whole process solution

get a quote

Enter product details or other specific requirements to receive an accurate quote. We will reply within 24 hours.